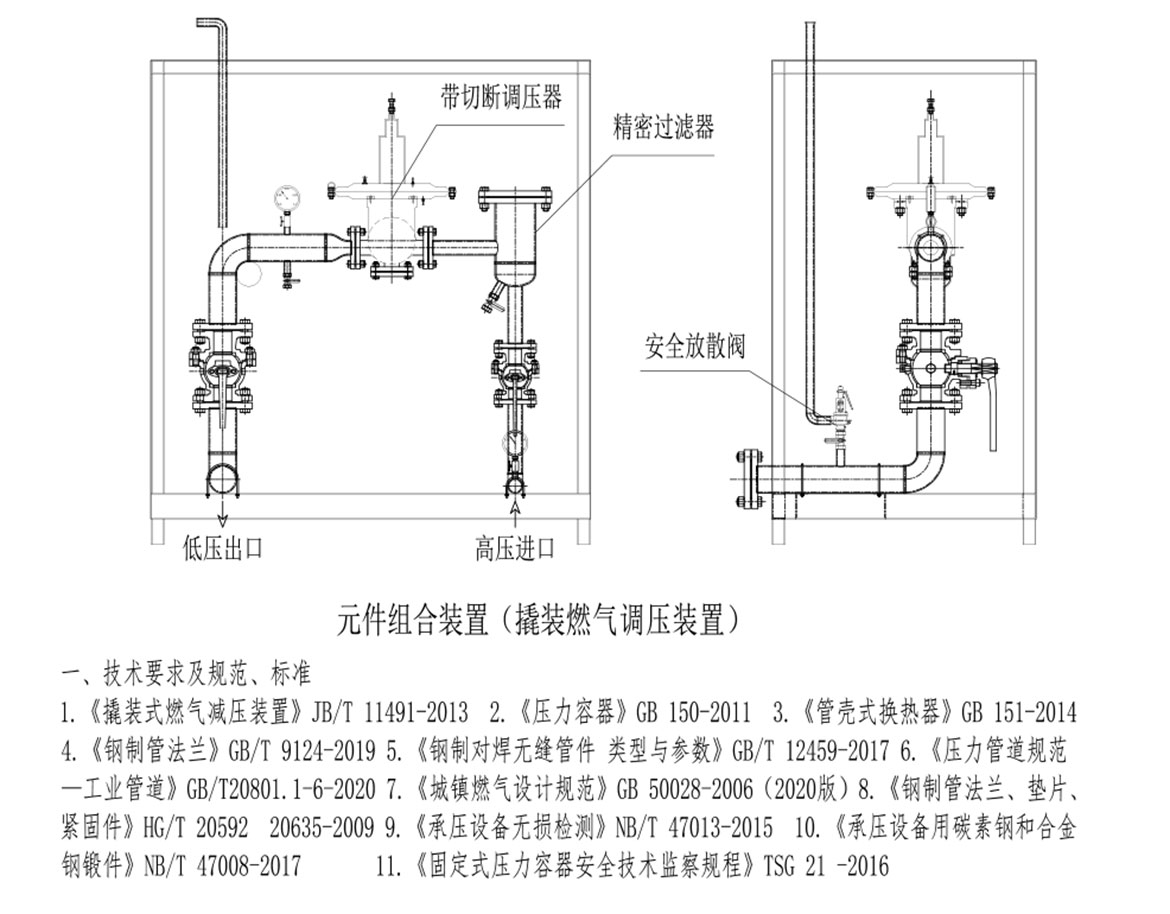

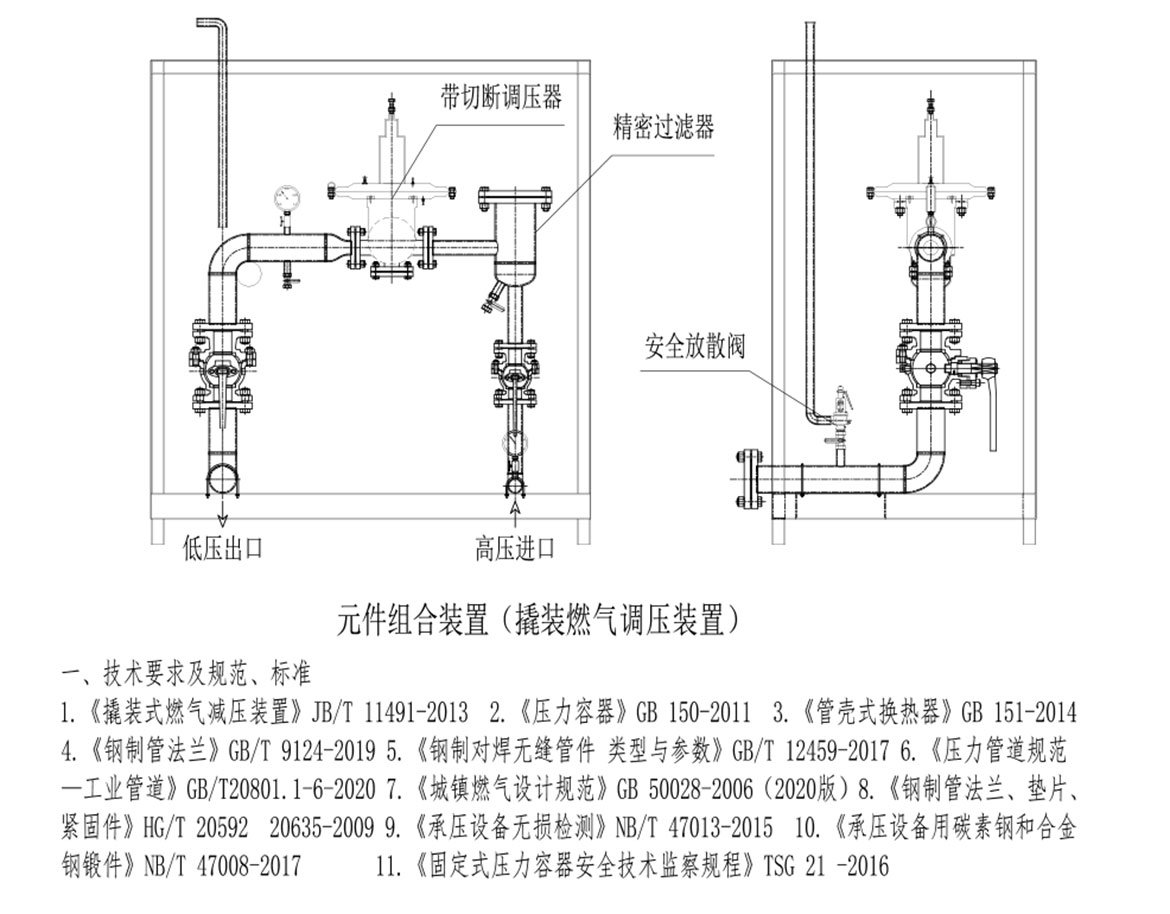

Skid-mounted gas regulator, which is characterized by a design of the whole factory, third-party supervision and inspection agencies qualified factory safety and quality assurance as well as ① no need to apply to the planning department to delineate the red line location, to solve the regulator station land acquisition is difficult, the location is not easy to determine the problem; ② canceled all the blocks of the low-pressure trunk pipeline, slowing down the contradiction of the tension of the pipeline on the road to save investment in pipeline networks; the use of medium-pressure transmission, the same delivery Under the condition of the same conveying capacity, the pipe diameter is reduced, which saves a considerable amount of money; ③ No need to build a house, which saves the cost of civil engineering; ④ Because the regulator is close to the user, the pressure fluctuation of the user is very small, which ensures the stability of the user's gas consumption; ⑤ The regulator cabinet has a good ventilation performance, the installation of the equipment is compact, and the total amount of overhauling is smaller than that of the regulator station.

The following figure shows:

It can be categorized by regulating mechanism:

Two-stage and three-stage pressure regulation (safety and security functions such as metering and emergency cut-off can be added)

The equipment is categorized by its arrangement and function:

Unloading system (high pressure hoses, quick release couplings, high pressure valves)

Heat exchange system (heat exchanger, temperature sensor)

Heating system (gas boiler, hot water pump, electric heating, etc.)

Pressure regulating system (high pressure emergency shut-off valve, regulator, filter, safety valve)

Measuring system (flow meter)

Control system (central console, operating cabinet)

Can be customized according to user needs design skid mounted gas regulator, function: unloading column, explosion-proof electric heating, secondary decompression, natural gas metering, over-limit safety automatic cut-off, automatic temperature control, leakage alarm cut-off, leakage, pressure, temperature and flow parameters integrated explosion-proof control box, acoustic and visual alarm (reserved 485 interface to the demand side of the interface to remote transmission to the DCS system), reinforced plastic spraying steel box, safety and explosion-proof quality and reliability. The quality is safe and reliable. Suitable for industrial kilns, gas boilers, district heating, restaurants and hotels, as well as direct-fired equipment pressure regulation, metering. Regional pressure regulating station, special regulating room, etc.

Dongguan Jinhe boiler Equipment Co., Ltd. specializes in boiler and boiler equipment, pressure vessels, pressure piping, environmental equipment design, manufacture, installation, renovation, maintenance, energy saving, energy contract one-stop professional services company.

Dongguan Jinhe boiler Equipment Co., Ltd. is located in the engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries."2015 Joint Jiangsu Quan Xin boiler factory R & D and production of high efficiency full condensing gas boiler, to achieve production, marketing, research and one-stop comprehensive services”

More than 20 years of industry experience, a number of equipment products have independent intellectual property patents

Design, manufacture, installation, renovation, maintenance, energy saving of boiler and boiler complete sets of equipment, pressure vessels, pressure pipes, environmental equipment

Engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries.

National Customer Service Center area of 2400 square meters of rapid response throughout the country after-sales service

Contact Us

National service hotline:13829262146

Address:No. 6, Road 1, Shegang Industrial Zone, Humen Town, Dongguan, China

TEL:0769-85245101

fax:0769-85247528

Email:13829262146@139.com

technical support:MYIT

Scan QR code to share to WeChat

0769-85245101