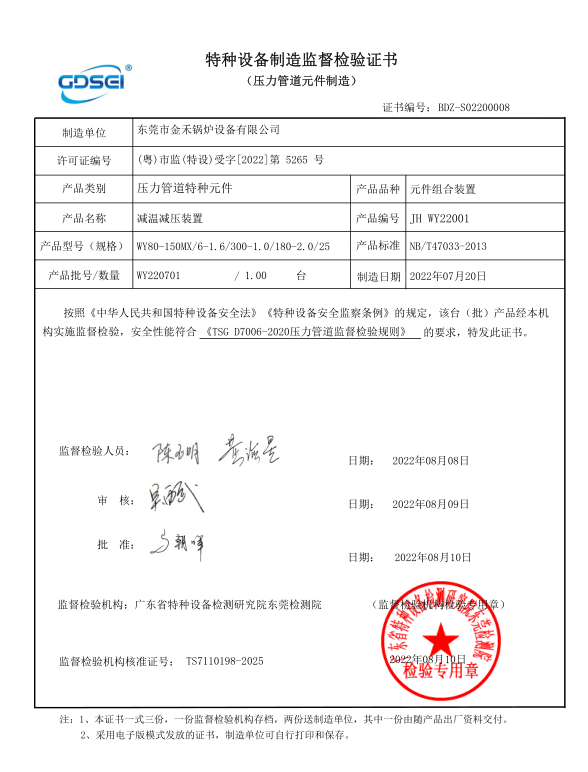

Temperature and pressure reduction device is widely used in modern industry in cogeneration, centralized heat supply (or steam) and light industry, electric power, chemical industry, textile and other enterprises in the thermal engineering of a steam thermal parameters (pressure, temperature) transformation device and the use of energy-saving devices for waste heat, through the device, the user to provide the parameters of the steam to the user to reduce the need for the appropriate temperature and pressure to meet the user's requirements, and can be fully conserved! It can also fully save heat energy and rationally utilize heat energy. Our company has a special equipment production license for temperature and pressure reducing devices, and every product has passed the supervision and inspection before leaving the factory, which is more stable and safe.

Principle of operation device introduction:

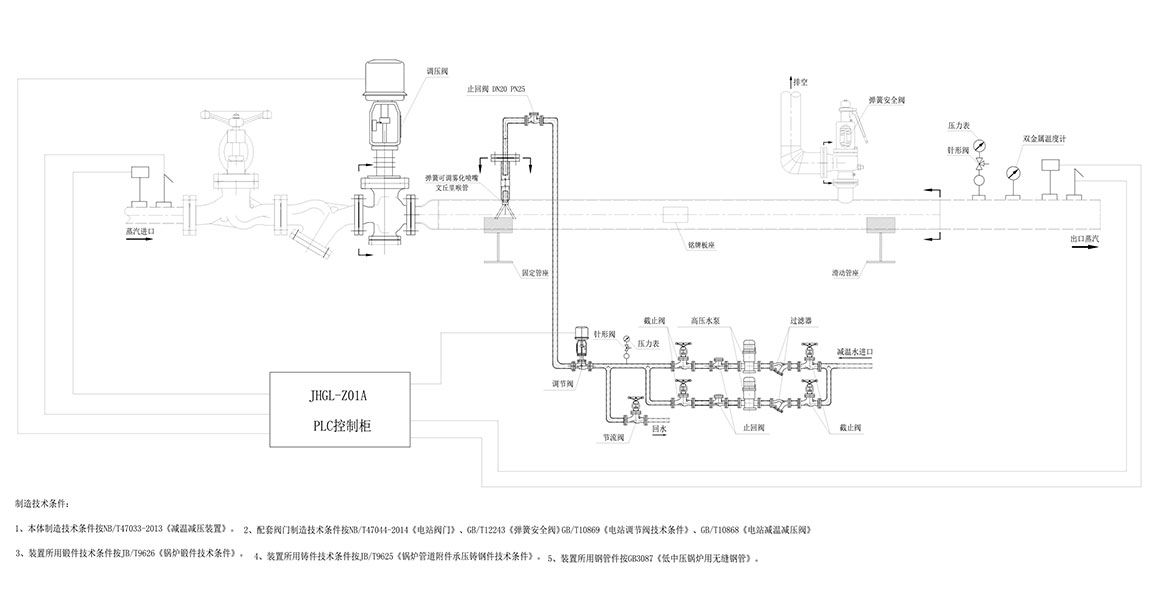

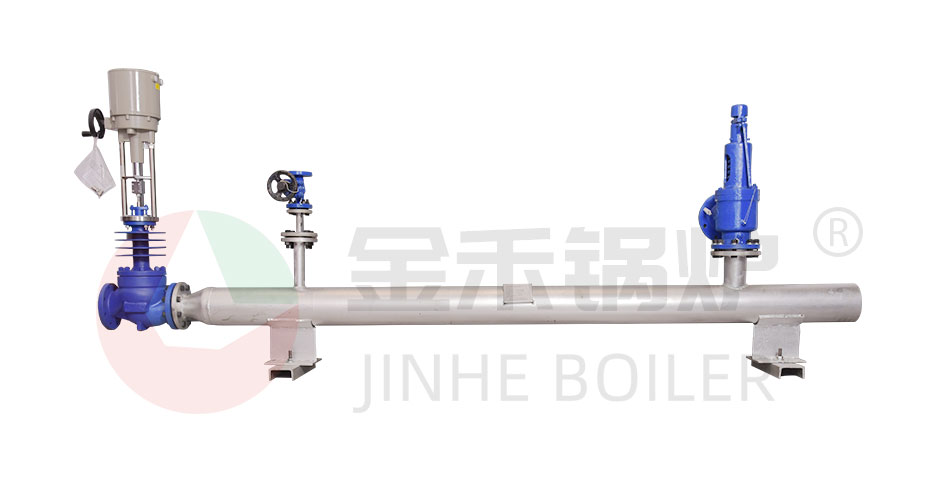

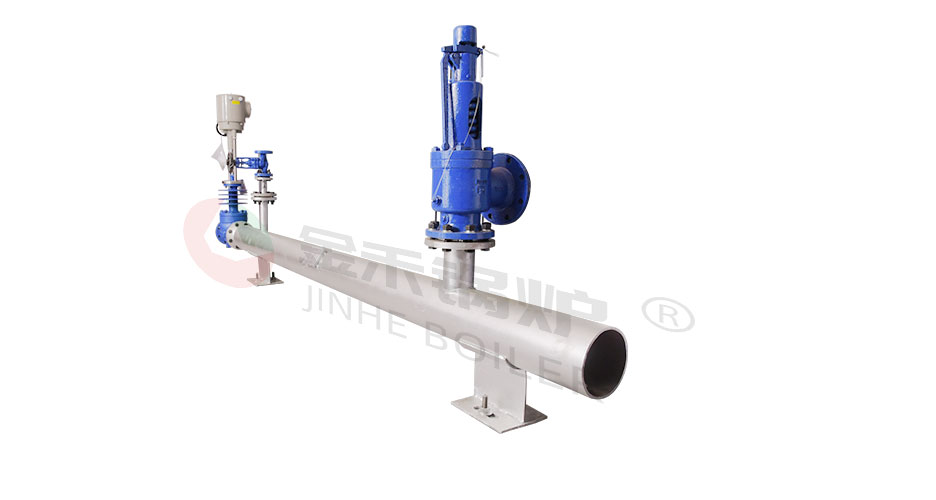

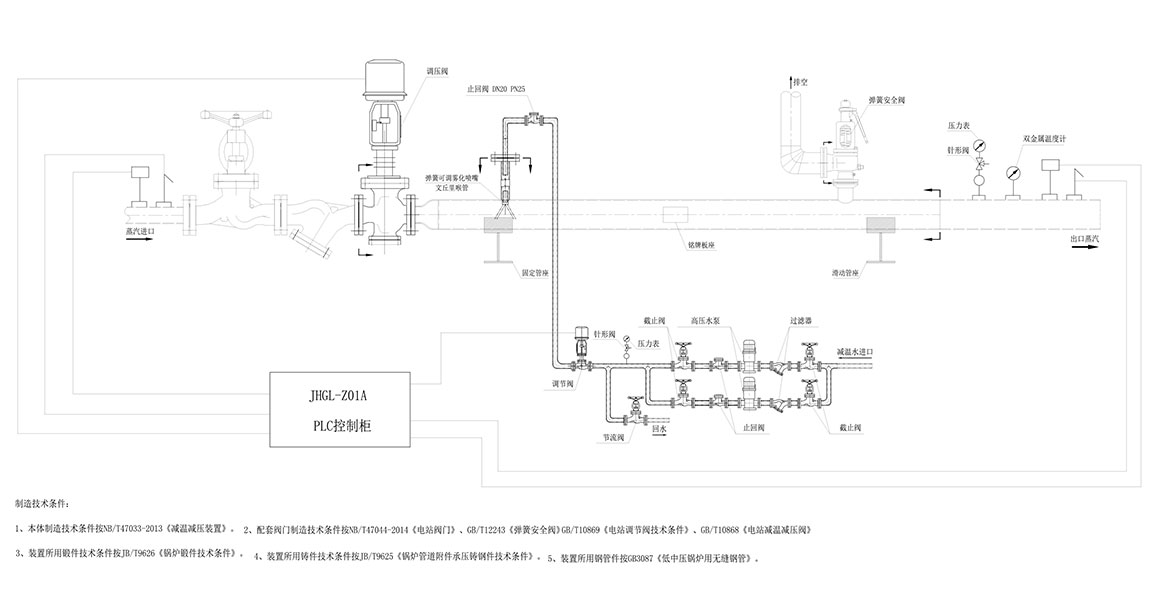

It consists of temperature reduction system, pressure reduction system, main steam pipe body, safety protection system, PLC thermal control system and so on. The specific form structure is shown below.

1, temperature reduction system: through the high-pressure differential control valve (or frequency pumps, etc.), the cooling water from different forms of nozzles to mist sprayed into the venturi pipe or steam piping steam, so that the steam temperature is reduced.

2、Pressure Reduction System: It consists of pressure reducing valve and throttling orifice plate. The pressure reducing valve achieves the purpose of regulating the pressure by changing the circulation area.

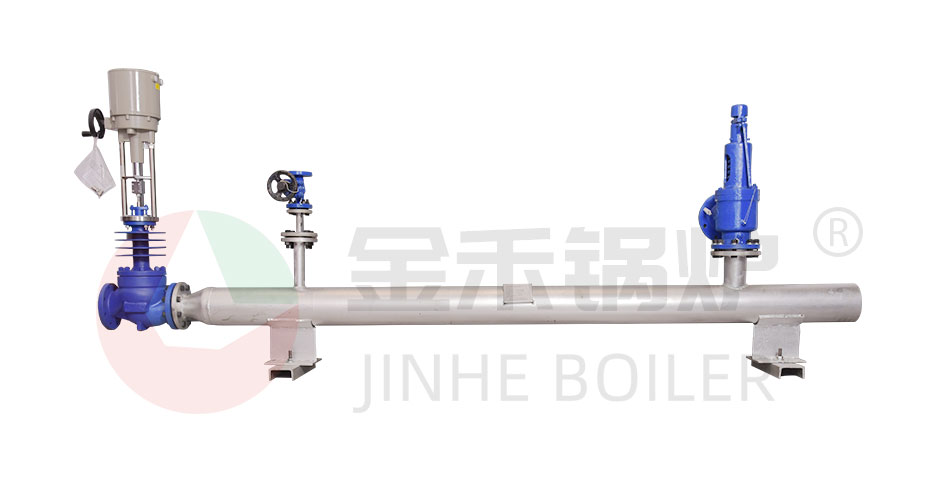

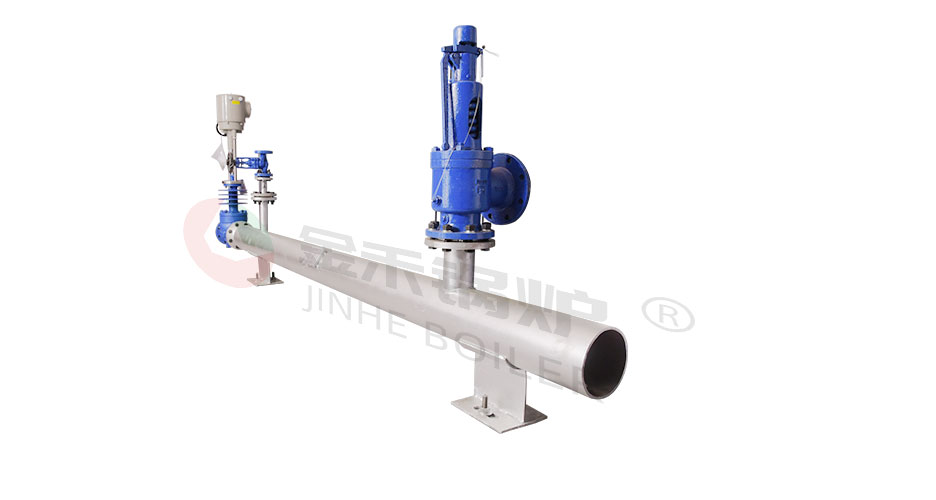

3、Main Steam Pipe Body:It is composed of mixing pipe and steam pipe etc.. According to the parameters provided by the user to decide, is the main body of temperature and pressure reduction device equipment, the purpose is to reduce the temperature and pressure after the steam sent to the user needs pipeline.

4, temperature and pressure reduction device safety system: in order to prevent the secondary steam pressure exceeds the specified value, automatically open the safety valve so that excess steam discharge, to achieve pressure reduction and safety protection, due to different parameters, there are the following structural forms, selected by the design of the plant.

①with spring safety valve

②with impulse and main safety valves (one or more sets)

③with lever safety valve

5, temperature and pressure reduction device thermal control system: is an important device to regulate the parameters of the steam outlet, through the receipt of the outlet temperature, pressure signals, after information processing, the command actuator so that the parameters of the outlet (temperature, pressure) stabilized in the user's requirements within the scope of the realization of automatic adjustment. The control system can also be adjusted manually.

The pressure reducing system adopts the structure of double-seat pressure reducing valve, which has small unbalance force, large adjusting range, smooth action and no jamming phenomenon.

specificities

The temperature reduction system adopts the method of venturi and spring adjustable nozzle, without transmission parts, with good atomization effect of temperature reduction water and easy disassembly and installation of the nozzle for maintenance.

Separate pressure reduction system and temperature reduction system, mainly used for poor working conditions, such as small steam flow is not suitable for the use of temperature reduction valve, and saturated steam conditions (lower pressure is mainly considered lower steam flow rate) using venturi pipe temperature reduction mode, the temperature reduction water fully atomized to achieve the best temperature reduction effect.

The whole system adopts PLC programming automatic control to achieve the best temperature and pressure reduction effect.

norm

A, temperature and pressure reduction device according to the inlet pressure and temperature can be divided into.

1. Medium temperature and medium pressure desuperheating and depressurization device.

Primary steam parameters (import steam parameters): pressure P1 = 3.9MPa; temperature t1 = 450 ℃ pressure.

Secondary steam parameters (export steam parameters): Pressure P2 determined by the user requirements; temperature t2 = saturation temperature.

Flow rate: Q=2~360t/h (tons/hour)

2. Sub-high-pressure temperature and pressure reduction device.

Primary steam parameters (inlet steam parameters): pressure P1 = 5.4MPa; temperature t1 = 485 ℃ pressure.

Secondary steam parameters (export steam parameters): pressure P2 determined by the user requirements; temperature t2 = saturation temperature.

Flow: Q=20~200t/h (tons/hour)

3, high-temperature and high-pressure temperature and pressure reduction device.

Primary steam parameters (import steam parameters): pressure P1 = 10MPa; temperature t1 = 540 ℃ pressure.

Secondary steam parameters (export steam parameters): pressure P2 determined by the user requirements; temperature t2 = saturation temperature.

Flow rate: Q=30~240t/h (tons/hour)

B. Main technical indicators of temperature and pressure reducing device

1 Outlet flow rate of temperature and pressure reducing device

Temperature and pressure reducing device outlet steam flow range of 30% Q ~ 100% Q, special needs can be negotiated by the supply and demand sides.

2 Rated outlet steam pressure of temperature and pressure reducing device P2

The deviation range of the rated outlet steam pressure of the temperature and pressure reducing device is.

① when the rated outlet steam pressure is less than 0.98MPa, P2±0.04MPa

② When the rated outlet steam pressure is not greater than 3.82MPa, P2±0.06MPa

③ When the rated outlet steam pressure is greater than 3.82MPa, P2±0.15MPa

3 Rated outlet steam temperature t2

Rated outlet steam temperature must be above the saturation temperature (including saturation temperature)

Rated export steam temperature deviation range of the minimum value of the rated export steam temperature t2±5℃

4 Desuperheating and depressurization device problem noise

Temperature and pressure reducing device in normal operation, in the temperature reducing valve (pressure reducing valve) outlet center line of the same level downstream 1m at the measurement of its noise, the overall noise level is not greater than 85dB (A). If the user has special requirements, can be determined by the supply and demand sides to determine the solution.

It realizes pressure reduction without energy loss, and the steam supply can be increased by this equipment. Simple structure, no rotating parts, reliable operation. Convenient operation, easy maintenance, automatic adjustment. Energy-saving effect is remarkable.

The scope of supply for temperature and pressure reducing devices is within the mark, the main products are.

1, Pressure reducing system: temperature and pressure reducing valve, throttling orifice plate, etc.;.

2, temperature reduction system: feed water regulating valve, throttle valve, etc.;

3, safety system: safety cap, stop valve, etc.; 4, piping system: water supply regulating valve, throttle valve, etc.; 3, safety system: safety cap, stop valve, etc.

4, piping system: steam piping, transition pipe, desuperheating water pipe, etc.; 5, supporting accessories: cut-off valve, stop valve, etc.

5、Accessories:globe valve,bimetal thermometer and receiver,pressure gauge and three-way valve,bend mine,joint,flange,gasket,bolt,nut,washer.

Orders need to know (please provide when the contract).

(1), export steam flow Q, inlet steam pressure P1, temperature t1, export steam pressure P2, temperature t2.

(2), desuperheating feedwater pressure Pb, temperature tb; (3), the temperature of the feedwater.

(3), indicating the control mode; (dashboard control, DCS control, DCS monitoring)

(4), the control category: electric, pneumatic;.

When selecting a pneumatic actuator, you must also provide.

1) Acting form: air-open or air-closed; 2) Air source pressure; 3) Air supply pressure; 4) Air supply pressure; 5) Air supply pressure; 6) Air supply pressure

2) the pressure of the air source; 3) the electrical signal of the valve positioner

3) Provide electrical valve positioner signal; 4) Other special requirements should be specified or signed in a separate technical agreement.

4) Other special requirements should be indicated after agreement or sign a separate technical agreement.

Dongguan Jinhe boiler Equipment Co., Ltd. specializes in boiler and boiler equipment, pressure vessels, pressure piping, environmental equipment design, manufacture, installation, renovation, maintenance, energy saving, energy contract one-stop professional services company.

Dongguan Jinhe boiler Equipment Co., Ltd. is located in the engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries."2015 Joint Jiangsu Quan Xin boiler factory R & D and production of high efficiency full condensing gas boiler, to achieve production, marketing, research and one-stop comprehensive services”

More than 20 years of industry experience, a number of equipment products have independent intellectual property patents

Design, manufacture, installation, renovation, maintenance, energy saving of boiler and boiler complete sets of equipment, pressure vessels, pressure pipes, environmental equipment

Engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries.

National Customer Service Center area of 2400 square meters of rapid response throughout the country after-sales service

Contact Us

National service hotline:13829262146

Address:No. 6, Road 1, Shegang Industrial Zone, Humen Town, Dongguan, China

TEL:0769-85245101

fax:0769-85247528

Email:13829262146@139.com

technical support:MYIT

Scan QR code to share to WeChat

0769-85245101