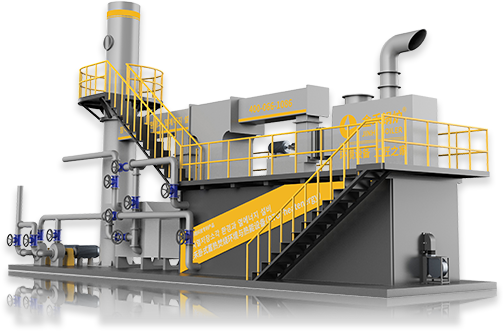

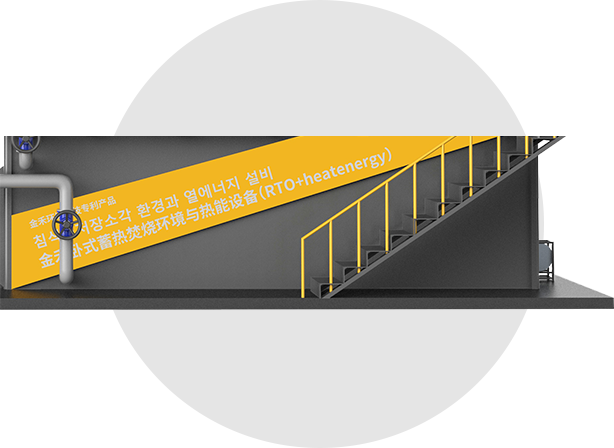

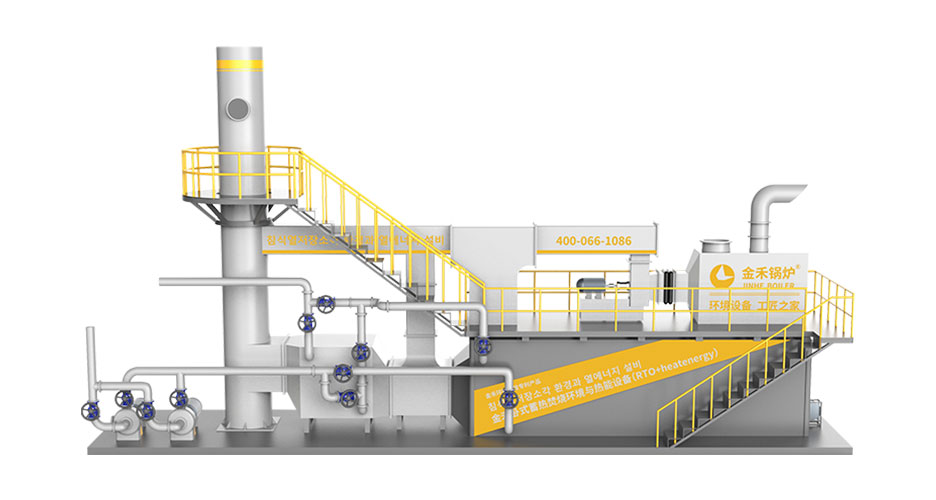

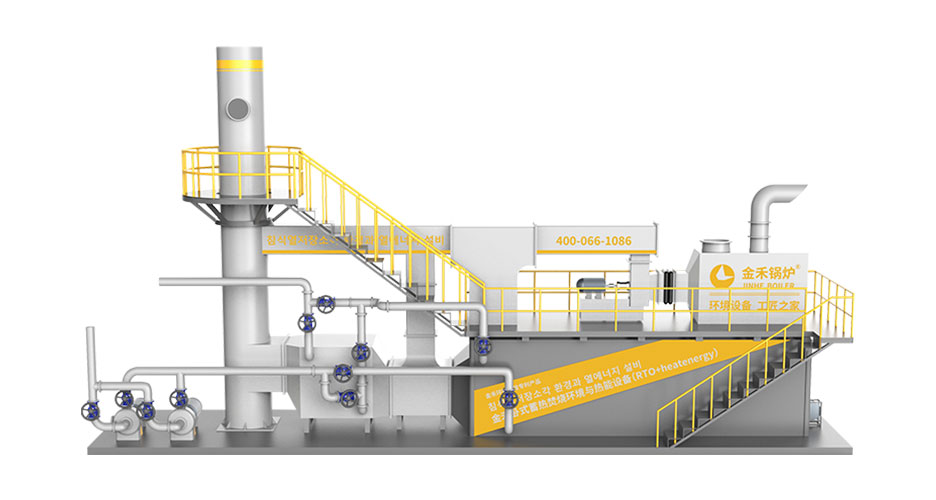

(RTO+heatenergy)

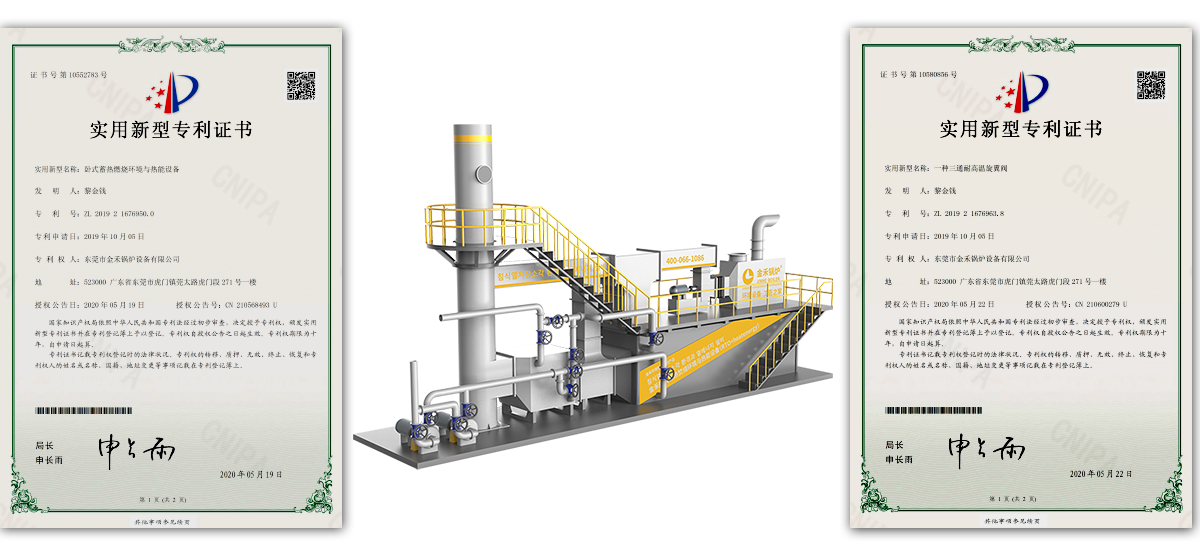

The equipment is Jinhe company has independent intellectual property patent products

———— Application number or patent number:201921676950.0

201921676963.8

In-depth study of customer demand for products and potential demand, practice and summary to find a better solution

ADVANTAGE

01

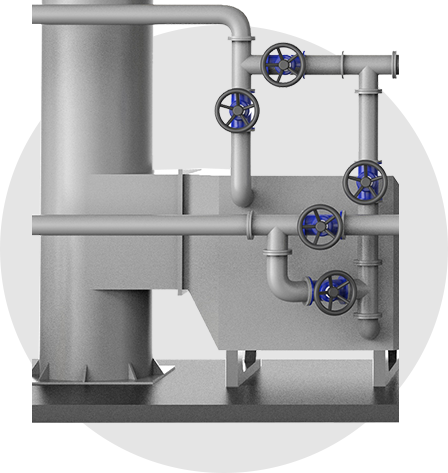

VOCS gas premixers

Controlling gas. concentrations to prevent deflagration

02

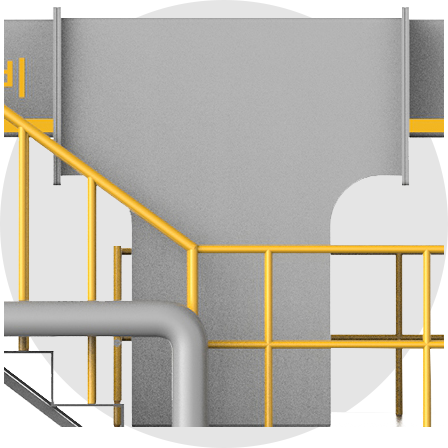

Horizontal regenerator

Internal settings V-type and M-type regenerator multiple regenerator alternately, not only to enhance the life of the regenerator, so that the VOCs exhaust gas completely incinerated oxidation, pollution-free emissions.

03

Heat energy recovery unit

According to user needs: thermal oil, steam, hot air, hot water secondary energy recovery efficiency of 98%

04

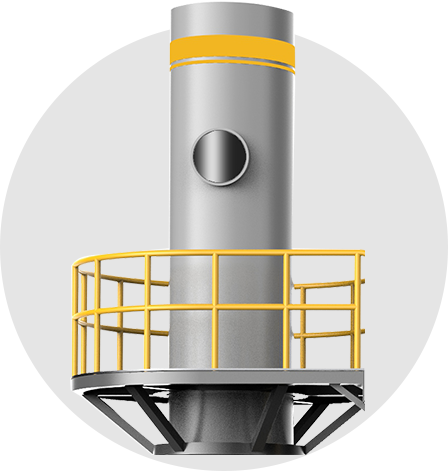

Flue gas detection platform

Convenient discharge side monitoring equipment maintenance and testing work

05

Automatic three-way high temperature rotor valve

Jinhe patented(Application number or patent number:201921676963.8)automatic three-way high-temperature rotor valve for air flow switching, so that the device regenerator in emergency repair or replacement of regenerator non-stop production for maintenance and replacement.

Dongguan Jinhe boiler Equipment Co., Ltd. specializes in boiler and boiler equipment, pressure vessels, pressure piping, environmental equipment design, manufacture, installation, renovation, maintenance, energy saving, energy contract one-stop professional services company.

Dongguan Jinhe boiler Equipment Co., Ltd. is located in the engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries."2015 Joint Jiangsu Quan Xin boiler factory R & D and production of high efficiency full condensing gas boiler, to achieve production, marketing, research and one-stop comprehensive services”

More than 20 years of industry experience, a number of equipment products have independent intellectual property patents

Design, manufacture, installation, renovation, maintenance, energy saving of boiler and boiler complete sets of equipment, pressure vessels, pressure pipes, environmental equipment

Engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries.

National Customer Service Center area of 2400 square meters of rapid response throughout the country after-sales service

Model specificationsModel specifications | VOCs processing capacity | treatment effect | matching thermal power | thermal efficiency | fuel | footprint area(L * W * H) |

| JHJ-W30 | 3000m³/h | >99% | 0.35mw/h | >96% | VOCs Gas + Natural Gas | 10000 * 2700 * 5500 |

| JHJ-W60 | 6000m³/h | >99% | 0.7mw/h | >96% | VOCs Gas + Natural Gas | 12400 * 3000 * 5500 |

| JHJ-W120 | 12000m³/h | >99% | 1.4mw/h | >98% | VOCs Gas + Natural Gas | 14500 * 4000 * 6500 |

| JHJ-W180 | 20000m³/h | >99% | 2.1mw/h | >98% | VOCs Gas + Natural Gas | 16000 * 4500 * 9000 |

Note: 1. The calorific value of natural gas is calculated according to 8500kcal/NM³; 2. The occupied area is the minimum area occupied by the equipment which can be reasonably planned according to the site; 3. The parameters of this picture and the picture are for reference only to prevail in kind.

Contact Us

National service hotline:13829262146

Address:No. 6, Road 1, Shegang Industrial Zone, Humen Town, Dongguan, China

TEL:0769-85245101

fax:0769-85247528

Email:13829262146@139.com

technical support:MYIT

Scan QR code to share to WeChat

0769-85245101