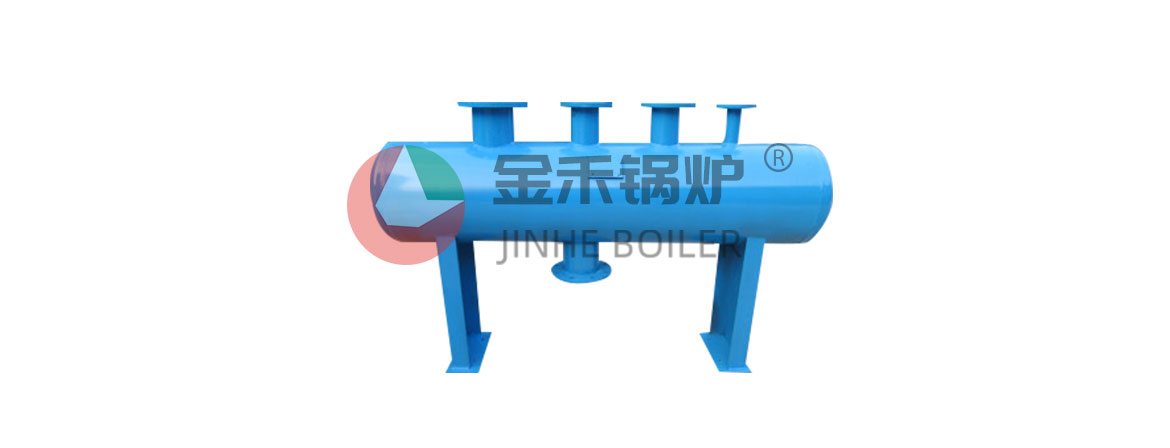

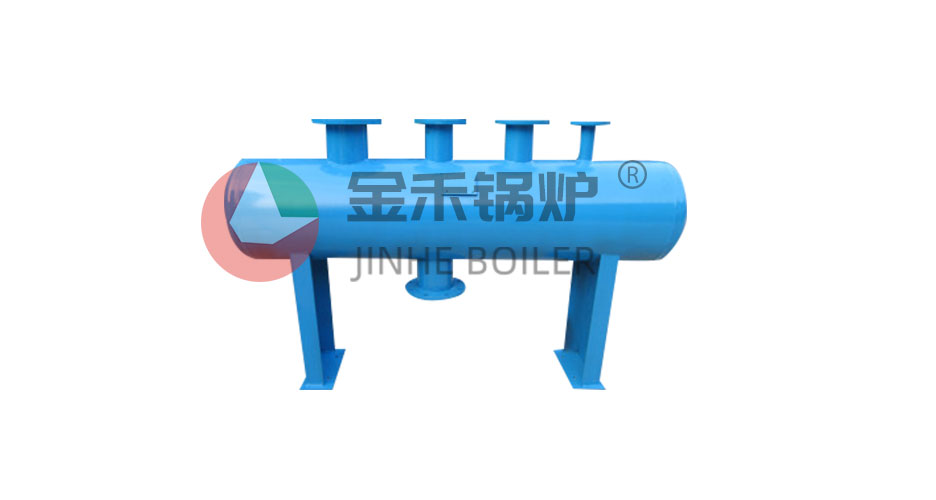

manifold

A manifold is a device used to connect the main heating supply pipe and the return pipe in a floor heating system. It is divided into two parts: water distributor and water collector. Water distributor is in the water system, used to connect the water supply pipe of each road heating pipe distribution device. Water collector is in the water system, used to connect each way heating pipe return pipe sink device.

The manifold is composed of a manifold and a collector, and the manifold is connected to the water supply pipe of the pipe network system, and its main role is to distribute the hot water from the pipe network system through the floor heating pipes buried under the floor to the indoor rooms that need underfloor heating. When the hot water flows in the underfloor heating pipe, the heat will be transferred to the floor, and then through the floor to the indoor radiation heat transfer.

Classification features

From the function and structure, water separator is divided into three types: basic, standard and functional.

Basic type: composed of water distribution pipe and water collection pipe. In each branch of the water manifold is equipped with a ball valve, while the water manifold is equipped with manual exhaust valves. The basic type water distributor does not have the flow adjustment function.

Standard type: standard type manifold structure and the basic type of the same, but the ball valve on the trunk pipe by the flow control valve instead. The manual exhaust valves on the two pipes are replaced by automatic exhaust valves. The standard type manifold can make precise adjustment of the flow of each loop, and even the flow adjustment of the deluxe standard type manifold can realize artificial intelligence adjustment.

Functional: Functional manifold in addition to all the functions of the standard type of manifold, but also has the temperature, pressure display function, flow automatic adjustment function, automatic water mixing and heat exchange function, heat measurement function, indoor partition temperature automatic control function, wireless and remote control function. The wireless thermostat supplied in the market, or the imported brand that realizes remote control, is the SAS816FHL-O/RF wireless floor heating thermostat of Samwell, but this thermostat is not programmable.

In order to prevent rust and corrosion, the manifold is usually made of corrosion-resistant pure copper or synthetic materials. Commonly used materials include copper, stainless steel, copper nickel-plated, alloy nickel-plated, high-temperature-resistant plastics and so on. The internal and external surfaces of the manifold (including connectors, etc.) should be smooth and clean, and there should be no defects such as cracks, sandholes, cold segregation, slagging, unevenness, etc. The surface plating of the connectors, the color and luster should be uniform, and the plating layer should be firm, and there should be no defects of de-plating.

In terms of design performance

From the design performance and other aspects are divided into, Korean version of the manifold, European version of the manifold. Korean floor heating due to the use of different habits and design concepts, usually relatively simple, coupled with the Korean floor heating on the room temperature control and time work requirements are not high, so its manifold does not need to bear too many functional requirements, the product is also relatively simple. More characteristic of the two sides of the two sides of the two baffles, but also two dry pipe support frame, usually butterfly-shaped manual valve to control the branch pipe water pass, break, manual exhaust, simple structure, wall-mounted installation. Korean-style water distributor structure is simple, simple function, low degree of intelligence, low cost, we will call it the Korean version of the water distributor.

The European brand of water separator is more fine workmanship, function is more perfect, in addition to the ability to regulate the flow, but also to meet the extension of many other functions, more intelligent and humanized. European-style water distributor is characterized by the upper and lower two dry pipe has a support frame fixed, branch pipe manual bonnet removal is easy to install thermoelectric actuator is convenient to do room temperature control. High-grade each branch has a visual flow meter, able to fine-tune the loop flow, and has a temperature gauge, pressure gauge, live knot ball valve, automatic exhaust valve. Equipped with a special distributor box, recessed wall mounting. European-style distributor structure is complex, powerful, high degree of intelligence, high cost, we will call it the European version of the distributor.

With the application and promotion of underfloor heating in some high-grade residences in the northern region, as well as the gradual development of heating in the southern region, the European-style intelligent water distributor is beginning to get more applications.

Korean version of the water distributor with its simple, inexpensive in the northern region of the popularization of floor heating and engineering projects are more applications.

The European version of the water distributor is mainly used in some high-grade projects and independent heating systems in the southern region due to its intelligence and high cost.

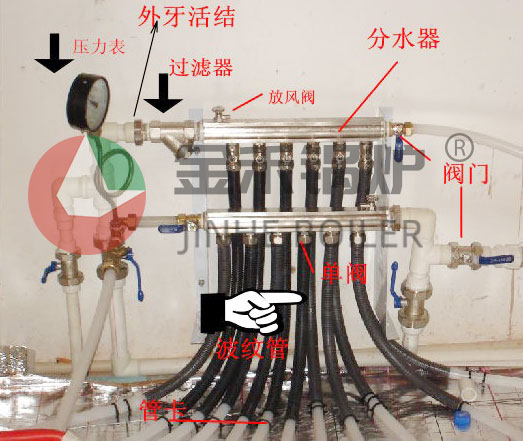

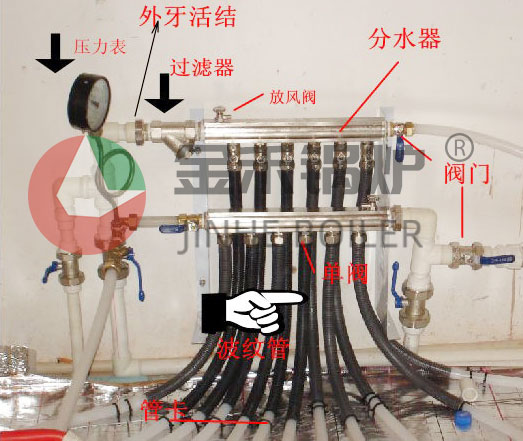

composition

The manifold as a connection between the loop heating pipe supply and return water distribution, water collection device, is a device in the floor heating system, plays a pivotal role. The manifold consists of three parts: the manifold, the collector and the fixed bracket. Including water distributor main (main bar), collector main (main bar), splitter regulator control valves, exhaust valves, main plug, wall plates and panels (bracketed manifolds do not have panels) and other components. The main accessories are manifold, collector, filter, valve, vent valve, locking valve, live knuckle head, inner knuckle head, heat meter.

The role of the exhaust valve (bleeder valve) on the manifold is: so that in the process of use, to bring convenience to the user, to avoid the hot and cold pressure difference as well as replenishment of water and other factors caused by the collection of gas, and make the system operation is impeded. With the exhaust valve (bleeder valve) can be deflated in a timely manner, there are two kinds of manual or automatic exhaust valve, as far as possible to install automatic exhaust valve.

Performance indicators

(1) Technical requirements for manifolds include.

1) sealing performance. According to the specified test method for hydraulic sealing test, water distributor leakage at each valve shall not be greater than 1mL/min. the total amount of leakage of water distributor connection parts shall not be greater than 1mL/min.

2) Hydraulic strength. Hydraulic strength test according to the test method, the distributor body is not allowed to have leakage, other parts are not allowed to affect the normal use of residual deformation.

3) Corrosion resistance. Aluminum casting surface must be anodic oxidation treatment, the surface of other materials shall have corrosion resistance or corrosion-resistant treatment. After the test, there should be no pitting pits visible to the naked eye, or peeling, and can be operated normally.

4) Valve fittings and passages. There shall be a valve device on the water outlet of the distributor, and the valve diameter shall not be smaller than the diameter of the water outlet of the distributor.

5) Valve opening force. Valves should be opened and closed flexibly, without jamming phenomenon, the maximum opening force should be in line with the relevant provisions.

(2) water collector technical requirements include.

1) sealing performance. Water collector in the nominal pressure, according to the provisions of the sealing test, in addition to the valve, the connection parts are not allowed to have leakage phenomenon, the nominal diameter of 150mm valve, the leakage shall not be greater than 15 drops / min. the rest of the valve leakage shall not be greater than 10 drops / min.

2) hydraulic strength performance. In 1.5 times the nominal pressure, according to the provisions of the hydraulic strength test, water collector body is not allowed to have leakage phenomenon, parts are not allowed to have cracks, are not allowed to affect the normal use of the residual deformation.

3) Corrosion resistance. After the water collector is tested, there should be no layer peeling or pitting pits visible to the naked eye, and it can be operated normally.

Common Brands

Imported brands of manifolds are: Italy's Giacomini GIACOMINI, Italy's EMMETI, Britain's ESACOSON ESAKCN, Germany's OVENTROP, Denmark's Danfoss DANFOSS, Britain's Samwell SASWELL and so on. Domestic Edison; Manfred. Konneford, Emeco Amico and so on. Better feedback on the market using the brand is basically also based on European brands, but the price will be more expensive than the national brand about double.

Purpose

1. Floor heating system, manifold management of a number of branch piping, and installed on it with exhaust valves, automatic thermostatic valves, etc., generally more copper. Small caliber, mostly DN25-DN40. More imported products.

2. air-conditioning water system, or other industrial water systems, the same management of a number of branch pipelines, respectively, including the return branch and water supply branch, but the larger bit more DN350-DN1500, etc., made of steel, belonging to the pressure vessel class of professional manufacturing companies, which need to be installed pressure gauge thermometer, automatic air venting valves, safety valves, venting valves, etc., the need to install between the 2 containers of pressure regulating valves, and the need for automatic bypass piping. And need to have automatic bypass piping assistance.

3. Tap water supply system, the use of water distributor effectively avoid the loopholes in the management of water, centralized installation, management of water meters, and with the use of single-pipe multi-channel to reduce the cost of pipe procurement, but also greatly reduces the construction time and improve efficiency. The tap water distributor is directly connected to the aluminum-plastic main pipeline through the reducer, and the water meter is centrally installed in the water meter pool (water meter room), so that there is one meter for each household, and it can be installed outdoors and viewed outdoors.

Installation Requirements

1. The distributor is installed on the wall and in the special box, and it is generally installed in the kitchen room in the residence.

2. The valve under the water collector is installed horizontally at a distance of more than 30 cm from the floor.

3. The water supply valve is installed in front of the water distributor, and the water return valve is installed behind the water collector.

4. The filter is installed in front of the water distributor.

5. Distributor connection order: connected to the water supply pipe - lock valve - filter - ball valve - tee (temperature, pressure gauge, interface) - water distributor (upper bar) - geothermal pipe - water collector (lower bar) - ball valve - connected to the return pipe.

Caution.

Floor heating manifold is mainly composed of manifold main and collector main, the manifold main is connected to the water supply pipe of the pipe network system, its main role is to distribute the hot water from the manifold of the pipe network system through the floor heating pipe buried under the floor to the indoor rooms needing underfloor heating, hot water in the underfloor heating pipe flow, the heat will be transferred to the floor, and then through the floor to the indoor radiant heat transfer. The other end of the underfloor heating pipe is connected to the collector of the manifold, and the return water with reduced temperature after indoor heat dissipation is returned to the pipe network system through the collector to complete a cycle.

Floor heating manifold is the control center of the whole indoor geothermal heating, almost all the equipment in the floor heating system, the realization and extension of the function of the device are dependent on the manifold. In practice, when the heat medium flows into the room, it enters the main bar of the manifold through the multifunctional filter, and the filter filters out the impurities in the heat medium in order to prevent the impurities from entering into the underground pipeline network and blocking the pipeline.

The main bar is installed horizontally, so that the use of the same height, the principle of equal pressure, so that the heat medium is evenly distributed to the branch lines, after the heat exchange system, the branch lines flow back to the collector back to the main bar, and then by the return flow into the heating system. In addition, there is a water mixing device in the self-heating, that is to say, after the heat exchange, the temperature of the heat medium (water) is still very high, and after the water mixing system, it flows back into the main bar of the manifold to continue the cycle, so that energy can be saved at the same time as heating.

Product Selection

The manifold is the key component of the low-temperature hot water underfloor heating control system, with the advantages of water underfloor heating accepted by more and more people, the importance of the quality of the manifold is also gradually recognized, but there are a variety of types of manifolds on the market, the good and bad products are mixed, and leakage of manifolds occurs from time to time. Therefore, consumers need to understand the quality of the manifold before choosing floor heating products, it is recommended that the best choice of imported brands. Below, I will give you a brief introduction to grasp the quality of the manifold several points.

Material and process structure

In order to ensure the quality of the manifold, the manufacturers have been from the product materials and process structure on the brain. From the material point of view, the market has stainless steel, copper, polymer synthetic materials, etc.; From the structure point of view, there are assembled, welded, forged splicing and so on.

The market can best embody the water collector material and structure of the unity of the whole forged brass one-piece water collector. Brass forging as a whole not only from the structure of the product to solve the problem of leakage of other manifolds, but also from the material to effectively eliminate the leakage of the hidden danger of the manifold. Such as Senville manifold SASF4 series floor heating manifold introduction of high-precision CNC lathe production spool, high concentricity, wear-resistant. Standard flow meter, automatic exhaust valve, drain valve and other important parts. The use of hot-extruded copper nickel-plated, corrosion-resistant, pressure-resistant, thick mounting bracket, flexible pipe joints, easy to install and maintain, firm, and greatly improve the service life and reliability of the product. The water volume of each return path of the manifold can be adjusted, and can be installed in each branch of the optional electric thermostat controller, geothermal thermostat, you can easily realize the intelligent control of zoning. Other imported brands also have integrated manifold, the function is not much different, customers see reference to the relevant information.

The market manifold due to different structural forms, installation and use there are also great differences. The most common copper manifold, for example, assembled manifold due to the production process is simple, low technical requirements of equipment, was chosen by many manufacturers, valve manufacturers and even general mechanical manufacturing enterprises, as long as they have the machining capacity, can produce such a manifold, so this manifold in the market accounted for the highest proportion. Of course, there are many production process control strict, reliable quality of the manifold, many well-known foreign brands have been extended with this structure. This type of manifold due to the joints, once the process control is not strict, it is easy to leak. Another type is the whole forging or casting of the manifold, greatly reducing the assembly nodes, effectively eliminating many of the leaks that may arise from the hidden danger point, is the existing market visible manifold more ideal structure.

In the form of a connection

Due to the use of water separator environment is often subject to the impact of hot and cold water, so the general sealing material is easy to aging damage. The use of O-ring or gasket coupling, in the repeated and frequent impact of hot and cold water, generally 2-3 years will need to be replaced or repaired. Therefore, some high-end foreign brands and domestic manufacturers with hard seal coupling production equipment and technology, are used between the metal hard seal coupling. Some small domestic manufacturers due to the level of production technology does not meet the requirements of the product precision does not meet the requirements of the hard seal, coupled with the selection of materials on the pursuit of cheap, docking materials do not do the corresponding complementary compression, it is often difficult to do the hard seal. So to ensure the quality of the manifold, it is wise to choose the hard seal coupling.

From the manufacturing process

Manufacturing process control is necessary to ensure the quality of the manifold. Processing precision is not high, assembled products are easy to loosen, advance valve stem surface finish does not meet the requirements, etc., will seriously affect the service life and quality of the manifold, and even directly lead to leakage of the manifold. So I suggest that consumers in the choice of manifold must understand the structure of the product, manufacturer, materials, after-sales service and other related information. Choose the reasonable structure, after-sales service is guaranteed genuine cost-effective products.

In terms of quality performance

Such as the boiler's thermal power output to be distributed through the reasonable distribution of the manifold, a low-grade simple type of manifold is likely to cause the system's circulation is not smooth, and make the boiler reflects the lack of combustion or other failures; in the case of meeting the sub-compartmental temperature control, the length of the coils is difficult to ensure that the length of the length of the proximity of the low-grade simple type of manifolds can not be adjusted to the ring of pressure loss, balancing the flow rate, it may result in a hydraulic imbalance, under-flow or over-flow that Make the local non-heat or overheat. And the use of an intelligent water distributor capable of flow regulation to solve this problem is relatively easy; room temperature control system also depends on a high-grade intelligent water distributor, easy to install control devices, you can control the system room temperature, running time, to achieve comfort, energy saving and humanized purpose. There are also, for example, intelligent temperature control center adjustment system, climate compensation adjustment system, differential pressure adjustment of the system, flow regulation and so on.

Dongguan Jinhe boiler Equipment Co., Ltd. specializes in boiler and boiler equipment, pressure vessels, pressure piping, environmental equipment design, manufacture, installation, renovation, maintenance, energy saving, energy contract one-stop professional services company.

Dongguan Jinhe boiler Equipment Co., Ltd. is located in the engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries."2015 Joint Jiangsu Quan Xin boiler factory R & D and production of high efficiency full condensing gas boiler, to achieve production, marketing, research and one-stop comprehensive services”

More than 20 years of industry experience, a number of equipment products have independent intellectual property patents

Design, manufacture, installation, renovation, maintenance, energy saving of boiler and boiler complete sets of equipment, pressure vessels, pressure pipes, environmental equipment

Engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries.

National Customer Service Center area of 2400 square meters of rapid response throughout the country after-sales service

Performance indicators

(1) Technical requirements for manifolds include.

1) sealing performance. According to the specified test method for hydraulic sealing test, water distributor leakage at each valve shall not be greater than 1mL/min. the total amount of leakage of water distributor connection parts shall not be greater than 1mL/min.

2) Hydraulic strength. Hydraulic strength test according to the test method, the distributor body is not allowed to have leakage, other parts are not allowed to affect the normal use of residual deformation.

3) Corrosion resistance. Aluminum casting surface must be anodic oxidation treatment, the surface of other materials shall have corrosion resistance or corrosion-resistant treatment. After the test, there should be no pitting pits visible to the naked eye, or peeling, and can be operated normally.

4) Valve fittings and passages. There shall be a valve device on the water outlet of the distributor, and the valve diameter shall not be smaller than the diameter of the water outlet of the distributor.

5) Valve opening force. Valves should be opened and closed flexibly, without jamming phenomenon, the maximum opening force should be in line with the relevant provisions.

(2) water collector technical requirements include.

1) sealing performance. Water collector in the nominal pressure, according to the provisions of the sealing test, in addition to the valve, the connection parts are not allowed to have leakage phenomenon, the nominal diameter of 150mm valve, the leakage shall not be greater than 15 drops / min. the rest of the valve leakage shall not be greater than 10 drops / min.

2) hydraulic strength performance. In 1.5 times the nominal pressure, according to the provisions of the hydraulic strength test, water collector body is not allowed to have leakage phenomenon, parts are not allowed to have cracks, are not allowed to affect the normal use of the residual deformation.

3) Corrosion resistance. After the water collector is tested, there should be no layer peeling or pitting pits visible to the naked eye, and it can be operated normally.

Contact Us

National service hotline:13829262146

Address:No. 6, Road 1, Shegang Industrial Zone, Humen Town, Dongguan, China

TEL:0769-85245101

fax:0769-85247528

Email:13829262146@139.com

technical support:MYIT

Scan QR code to share to WeChat

0769-85245101