Compressed air tanks, generally called compressed air storage tanks, or compressed air buffer tanks.

Generally, after coming out of the air compressor, it is dried and filtered (or directly) into the compressed air tank.

Because the air is easy to be compressed, as well as the pressure of the air user point of the variability of the amount of air.

The compressed air tank can keep the compressed air pressure stable, as well as the smooth operation of the air compressor.

Avoid pressure fluctuation, or air compressor frequent startup or frequency conversion resulting in shortening the life of the air compressor, as well as a waste of electricity.

One more thing: compressed air tanks are pressure vessels. Need to be registered in the local quality and technical supervision bureau (pot inspection institute) for the record. Before put into use, must obtain the pressure vessel is the use of license.

Compressed air tank is a very important part of the entire air compressor system, the general use of air pressure equipment companies will use compressed air tanks, compressed air tanks are generally divided into two types of materials: carbon steel and stainless steel. The specific selection can be based on the use of the industry.

Carbon steel tanks according to the hardness and toughness of the steel plate including Q235-B carbon steel and Q345R low alloy steel, general Q235-B carbon steel material steel plate is mainly used for volume 2 cubic meters below, the pressure is less than or equal to 10bar compressed air tanks, this tank volume and pressure are small, the safety coefficient is slightly higher; and Q345R low alloy steel is mainly used for more than 2 cubic meters, the pressure is more than 10bar compressed air storage tank with high risk factor. Carbon steel storage tanks are suitable for most industries, such as environmental protection, textile, printing, automotive, electronics, etc.

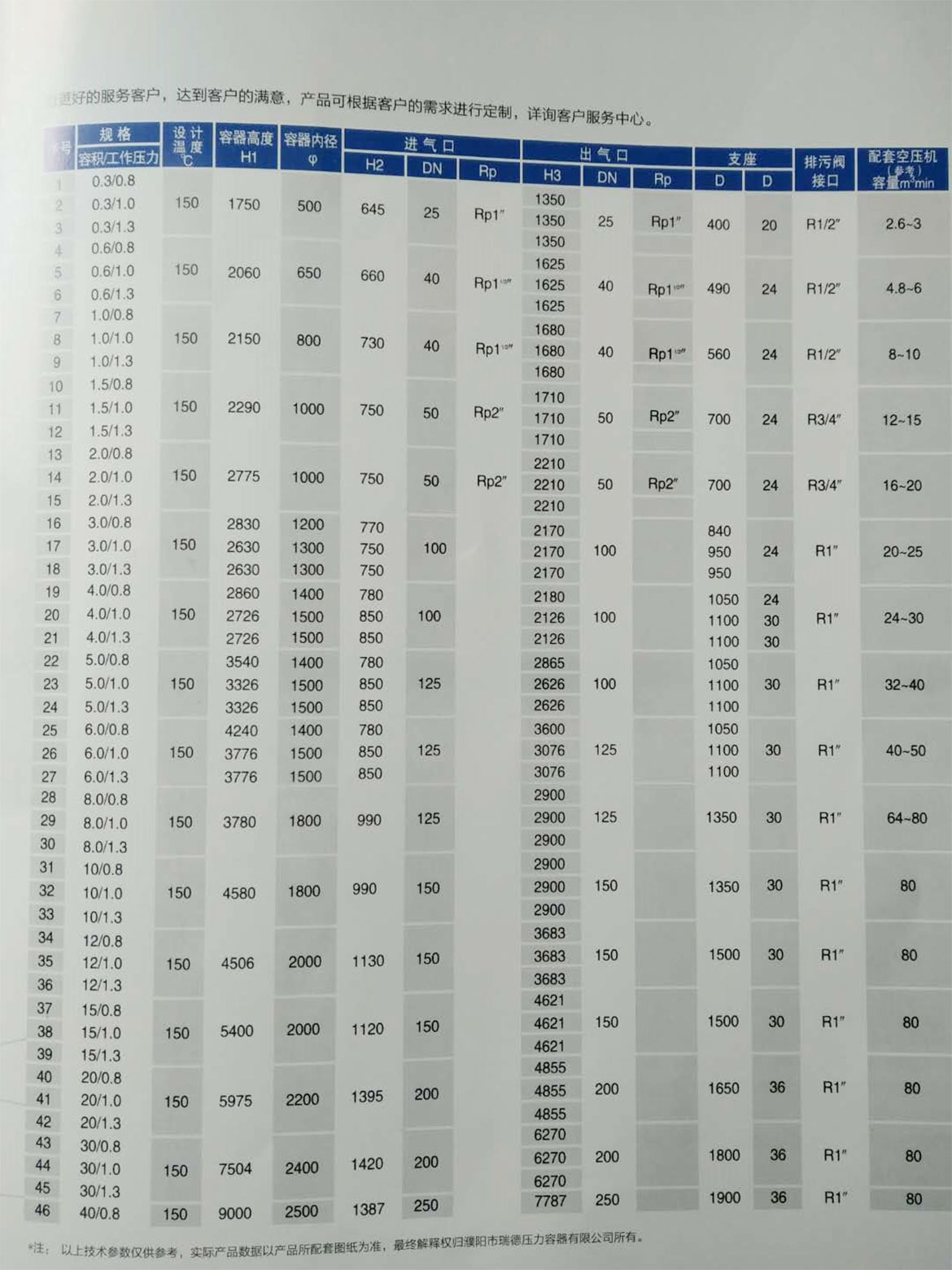

Stainless steel tanks mainly refers to the SUS304 material, the volume is generally more than 0.3 cubic meters, the pressure from 8bar to 70bar; stainless steel tanks are mainly used in some of the compressed air quality requirements of the enterprise, corrosion resistance is good, stainless steel corrosion resistance depends on the alloying elements contained in the steel. When choosing the brand of air storage tanks, try to choose a relatively large air storage tank manufacturers, quality and service are reliable, choose a good quality and performance of compressed air storage tanks, not only out of the air quality is good, stable operation of the air compressor, and the use of the tank's mission is also relatively long. Stainless steel tanks are mainly used in food, pharmaceutical, chemical, microelectronics and other industries.

First, the compressed air storage tank introduction

Air compression tank is also commonly referred to as air tanks, is a pressure vessel used to store air, compressed air tanks are mostly supporting the use of air compressors, to play a role in the storage of the buffer, to get rid of most of the liquid water, to avoid frequent loading of the air compressor, you can prolong the service life of the air compressor. Air compression tanks can be divided into a variety of different sizes according to the size of the tank, according to the different materials can be divided into carbon steel tanks and stainless steel tanks, according to the different pressures can be divided into simple pressure vessel tanks, atmospheric pressure tanks and high-pressure tanks.

Second, the role of compressed air storage tank

1, storage capacity: on the one hand, to solve the system in a short period of time may be more than the amount of gas supply contradictions, on the other hand, in the air sirenji failure or other sudden events (such as power outages) for temporary emergency;

2, stabilize the gas: eliminate or weaken the piston compressor output airflow pulsation, stabilize the pressure of the gas source, to ensure that the output airflow continuous and smooth;

3, precipitation impurities: further cooling air, separation and elimination of compressed air in the moisture, oil and other impurities, reduce the pipeline network downstream of other post-processing equipment workload, so that all types of air equipment to obtain the required quality of the air source; small air compressor comes with a storage tank is also used to be used as a compressor body and other accessories mounting base frame.

Third, compressed air storage tank selection:

1, the volume size of the storage tank should be 10% of the compressor discharge - 20%, we generally choose 15%, when the air volume is larger, the volume of the storage tank should be increased appropriately, if the site of the air volume is smaller, can be lower than 15%, it is best not to be lower than 10%.

2, the dryer and filter capacity should be consistent with the compressor discharge.

3、The filter before the dryer should be equipped with automatic drainer.

4, the use of adsorption dryer, the compressor should be reserved for the appropriate amount of gas consumption.

5, the dryer is installed in the storage tank, the role of the tank is more fully embodied, play a buffer, cooling and sewage effect, can reduce the load of the dryer, for the system to supply gas more uniform conditions. Dryer installed in the storage tank before the system can provide a larger peak adjustment capacity, mostly used for gas fluctuations in the working conditions.

Fourth, the application of compressed air storage tanks:

Air compression tanks are generally used in conjunction with air compressors, in addition to the application of air tanks in a wide range of industries, some instrumentation air, power execution, equipment blowing, process aids and other aspects will be used.

Textile industry. Mainly with compressed air to provide clean gas power for air jet looms, sizing machines, dyeing and finishing machines, roving machines, suction guns and so on;

Semiconductor industry. Where wafer oxidizing equipment, vacuum systems, pneumatic control valves, pneumatic handling devices, etc. need to work with air storage tanks in order to complete their operations;

Power industry. Gas storage tanks play a major role in pneumatic conveying, dry ash transportation, pneumatic actuation, promote instrumentation equipment;

Automobile tire industry. Its role is mainly to promote the steel cord fabric cut-off machine, vulcanizing machine, pneumatic smelting, pneumatic molding and so on;

Food industry. It is used to power filling machines, bottle blowing machines, packaging equipment etc.

Fifth, the air compressed gas tank annual inspection:

Air compression tanks belong to the pressure vessel, the need for registration in the local Quality Supervision and Inspection Bureau for the record, that is, the use of pressure vessels registration certificate, registration for the record can only be used after the record. For simple pressure vessels, that is, the volume is less than 1 cubic meters, the pressure is less than 8 kilograms of gas storage tanks, you can use directly without registration.

Sixth, air compression tank manufacturers:

Hubei Lingtan Electromechanical Equipment Co., Ltd. is a large pressure vessel production base, is recognized by the General Administration of Quality Supervision, Inspection and Quarantine of the D1/D2 level pressure vessel design, manufacturing units, is a high-tech enterprises, the factory has a fully automated pressure vessel manufacturing assembly line, can efficiently produce quality products. Hubei Yimudi Development Co., Ltd. mainly produces and sells: gas storage tanks, vacuum tanks, pressure tanks, diaphragm tanks, pressure stabilizer tubes, split cylinders and other pressure vessels.

The company covers a total area of 70,000 square meters, the existing production plant of 50,000 square meters, is a set of design, manufacturing, installation in one of the multi-functional all-round pressure vessel design, processing and manufacturing enterprises. After years of development, the company already has a pragmatic and efficient, technically excellent team, the proportion of research and development personnel is more than 20%, has 44 patents related to the manufacture of gas storage tanks, has obtained the pressure vessel design license, pressure vessel manufacturing license and other certificates, is committed to providing customers with safer and more efficient pressure vessel products.

Compressed air storage tank safety valve how to choose

General design institute will consider different failure overpressure conditions: such as fire, pipeline valve closure and other situations.

According to the overpressure situation, to determine the corresponding media displacement requirements, according to the amount of value of the inverse calculation of the required safety valve specifications can be.

As for the pipeline, calibration pressure and other factors are not a problem. 0.6MPa pressure is very easy, the import and export forms can be flexibly changed according to the actual situation.

Dongguan Jinhe boiler Equipment Co., Ltd. specializes in boiler and boiler equipment, pressure vessels, pressure piping, environmental equipment design, manufacture, installation, renovation, maintenance, energy saving, energy contract one-stop professional services company.

Dongguan Jinhe boiler Equipment Co., Ltd. is located in the engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries."2015 Joint Jiangsu Quan Xin boiler factory R & D and production of high efficiency full condensing gas boiler, to achieve production, marketing, research and one-stop comprehensive services”

More than 20 years of industry experience, a number of equipment products have independent intellectual property patents

Design, manufacture, installation, renovation, maintenance, energy saving of boiler and boiler complete sets of equipment, pressure vessels, pressure pipes, environmental equipment

Engineering department, production and operation department, equipment management department, quality inspection department, office management department and domestic 6 directly under branches, 2 independent subsidiaries.

National Customer Service Center area of 2400 square meters of rapid response throughout the country after-sales service

Contact Us

National service hotline:13829262146

Address:No. 6, Road 1, Shegang Industrial Zone, Humen Town, Dongguan, China

TEL:0769-85245101

fax:0769-85247528

Email:13829262146@139.com

technical support:MYIT

Scan QR code to share to WeChat

0769-85245101